中文版MessageContact usSitemapWelcome toShanghai MX-CEKONG Technology Co.,Ltd website!

中文版MessageContact usSitemapWelcome toShanghai MX-CEKONG Technology Co.,Ltd website!  中文版MessageContact usSitemapWelcome toShanghai MX-CEKONG Technology Co.,Ltd website!

中文版MessageContact usSitemapWelcome toShanghai MX-CEKONG Technology Co.,Ltd website!

400 662 6286

| Measuring range | 0.5 – 2.5 g /cc (500 – 2500 kg/m3) |

| Calibration range | 0.5 – 2.5 g /cc (500 – 2500 kg/m3) |

| Precision | ± 0.002 g /cc (± 2 kg/m3) |

| Repeat | ± 0.0002 g /cc (± 0.2 kg/m3) |

| Operation tem range | -50℃ ~ +200℃ |

| Maximum operation pressure | 207 bar (3000 psi) |

| Fluid viscosity range | 0 – 20000 cP |

| Tem-coefficient | Less than 0.1 kg/m3/℃ (after adjusted) |

| Pressure influence | Neglectable |

| Built-in tem sensor | digital sensor |

| Wetted material | 316L stainless steel and Hi-alloy |

| Coating of the fork body | Standard type,PTFE or Electrolytic polishing |

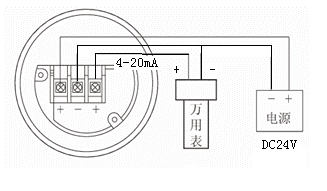

| Power supply | 24VDC,≥50 mA |

| Analog signal output | 4 -20 mA,0-1000Hz,RS485 Modbus RTU |

| Output precision(20℃) | ± 0.1% or ± 0.05% FS of the number |

| Output repeatability(-40 ~ +85℃) | ± 0.05% FS |

|

Process connection |

ANSI 150 ~ 1500 RF |

| DIN 50 PN16 DIN 50 PN40 | |

| IDF and RJT sanitary type | |

| Protection grade | IP65 |

| Shell | Aluminum alloy |

|

Install standard

|

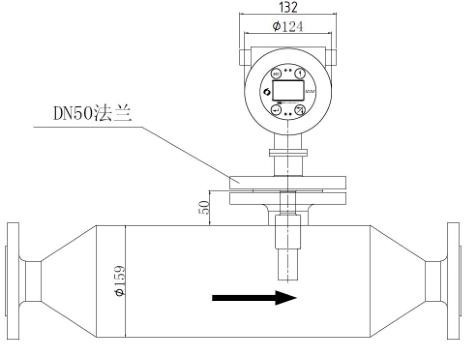

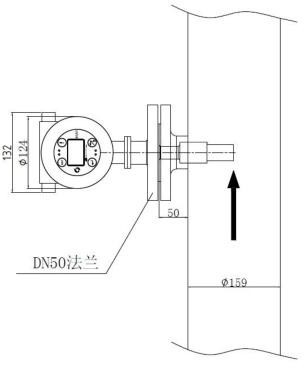

T-shape side open, inserting installation |

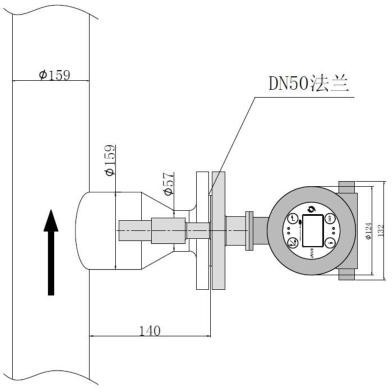

T-shape side open,indented installation |

|

|

Instruction |

part of the fork goes directly into the main body |

The open part of the fork body is indent to avoid the main body | |

| 25mm | |||

| Velocity | The velocity of flow through the fork: 0-1m/s | main pipe velocity: 1-5m/s | |

|

Viscosity range |

max 20000Cp |

max 100cP(special conditions can reach 250cP) |

|

| Tem | -50-150℃ | -50-150℃ | |

|

Main pipe size |

≥horizontal pipe 100mm(4″); |

≥50mm(2″) |

|

| ≥vertical pipe 150mm(6″); | |||

|

Advantages |

easy to install,high precision |

For mortar fluid, the wear of instrument can be reduced effectively |

|

|

Disadvantages |

Not applicable: | ||

|

Not applicable: |

1. | Cottony solution(ex:paper pulp) | |

|

1.unstable velocity |

2. | unstable velocity | |

|

2.main pipe caliber< DN100 |

3. | in cottony solution | |

| 4. | main pipe caliber< DN100 | ||

| 5. | A condition in which the temperature effect is significant | ||

|

|

|

|

HOTLINE